No products

PLUGS | COMPOSITE TOOLING | MOLD-MAKING

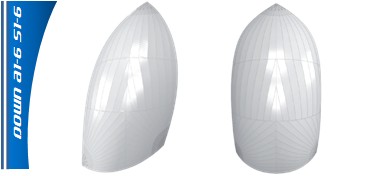

Serving shipyards for many years, our company supports you in the search for a mold tool maker and the production of large composite patterns and molds with complex shapes. With extremely diverse experience in the marine industry, sailboats, powerboats, trimarans, catamarans, we can also build plugs and molds for other industries including transport, food, mining or architecture. Discover a complete offer including design, pattern creation, mold manufacturing, but also boat equipment at different stages of construction. Composite material molds are intended for the production of differend laminated parts. Generally made of polyester resin and reinforced with fiberglass, large format molds can be mounted on steel frames to ensure good rigidity during handling and production. The molds are made from 5-axis machined masters. Various sectors of activity such as the automobile, railway or food industries call on these skills and qualifications for the design of patterns and the manufacture of molds for different parts, boxes, tanks, road crossing tubes and many others.

OUR CAPABILITIES

> Production of plugs and molds

> Production of plugs and molds as well as making of parts from these molds

> Manufacturing parts using your own molds

PRODUCTION

> Manufacturing of composite parts

> Partial equipment and installations: hull, deck, bottom coverings, structural parts, bulkheads

DESIGN & ENGINEERING | PLUG & MOLDS | PART FABRICATION

ORDERS PROCESS

> Study and analysis of the part to be produced

> Making a plug

> Finishing the plug

> Creation of the mold on the plug

> Unmolding the mold

> Mold finishing

> Tool quality control

> Delivery

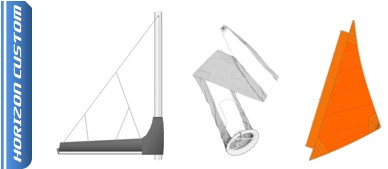

Mold Construction - Composite Parts Production

The plug is defined as the support on which the production tool is molded. Therefore, the attention paid during the manufacture of the plug is of capital importance since it determines the final quality of the mold. The modeling is carried out precisely according to the client's specifications. The modeling services (master model, master, preform) are adapted to customer expectations and needs and make it possible to give volume to 3D digital files to validate the shapes at real scale or even create the tooling for mass reproduction of a part. 5-axis milling makes it possible to manufacture plugs with complex shapes with high assembly precision of the different parts. Great importance is given to the quality of the achievements, in particular with regard to the rigidity of the structures, the dimensional respect and the surface condition of the models. The surfaces are then polished for perfect finish and shine. From 3D files, we create plugs of the deck, the hull, but also different parts such as covers, the helm station, the rudder, the centerboard. It is also possible to entrust us with your patterns and prototypes in order to present and validate your projects in design offices.